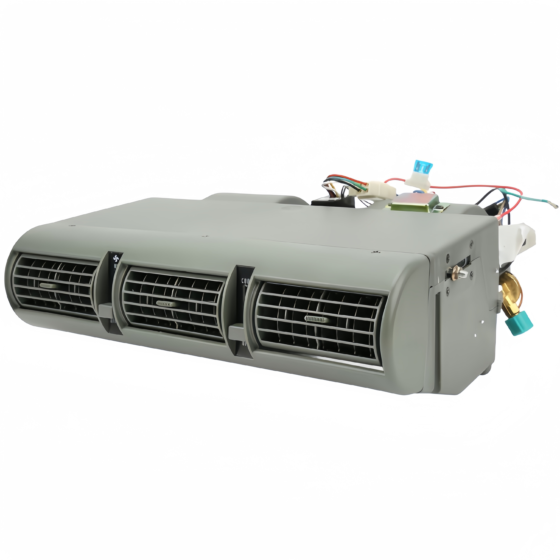

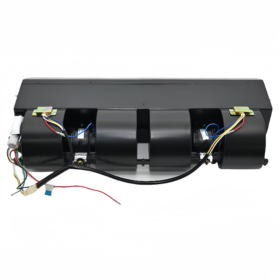

The automotive air conditioning evaporator is a crucial component of a vehicle’s HVAC (Heating, Ventilation, and Air Conditioning) system. Designed to provide a comfortable cabin environment by cooling and dehumidifying the air, the evaporator plays a significant role in ensuring passenger comfort, enhancing driving experience, and increasing the overall efficiency of the vehicle’s climate control system.

Function and Importance

The primary function of the evaporator is to absorb heat from the cabin air. It does this by utilizing the refrigerant, which circulates within the HVAC system. As the refrigerant passes through the evaporator coils, it evaporates, absorbing heat from the air drawn in by the vehicle’s blower fan. This process not only cools the air but also removes excess humidity, preventing fogging on windows and ensuring a clear view for the driver.

Key Functions:

- Cooling: Lowers the temperature of the air entering the cabin.

- Dehumidification: Reduces humidity levels, preventing moisture build-up.

- Air Quality Improvement: Enhances overall air quality by filtering out pollutants and allergens.

1. Material Selection

The evaporator is typically made from materials that provide excellent thermal conductivity and corrosion resistance. Common materials include aluminum and copper, which facilitate efficient heat transfer and durability.

2. Compact Design

Modern automotive evaporators are designed to be compact and lightweight, allowing for easy integration into various vehicle models without compromising space or performance.

3. Fin and Tube Configuration

The evaporator’s fin and tube design maximizes surface area for heat exchange. The fins increase the contact area for air, allowing for enhanced cooling efficiency. The tubes, through which the refrigerant flows, are designed to optimize the flow path and minimize pressure drop.

Performance Characteristics

1. Cooling Capacity

The cooling capacity of an evaporator is measured in BTUs (British Thermal Units) per hour. A well-designed evaporator can significantly impact the overall cooling performance of the vehicle’s air conditioning system.

2. Airflow Rate

The efficiency of the evaporator is also determined by the airflow rate. The higher the airflow rate over the evaporator fins, the more effective the cooling process becomes.

3. Pressure Drop

Minimizing pressure drop across the evaporator is essential for maintaining optimal refrigerant flow and system efficiency. Engineers focus on designing evaporators that balance thermal performance with low resistance to airflow, ensuring that the HVAC system operates smoothly and efficiently.

.

1. Installation Guidelines

Proper installation of the evaporator is crucial for optimal performance. The evaporator should be mounted securely within the HVAC unit, with all connections sealed to prevent refrigerant leaks. It is essential to follow manufacturer specifications regarding orientation and mounting to ensure that airflow is directed efficiently across the fins.

2. Regular Maintenance

To maintain the efficiency of the evaporator, regular maintenance is necessary. This includes:

- Cleaning: Dust and debris can accumulate on the fins, reducing airflow and cooling efficiency. Periodic cleaning using compressed air or specialized cleaning solutions is recommended.

- Inspection for Leaks: Regularly checking for refrigerant leaks is vital. Any sign of leakage can drastically reduce cooling performance and should be addressed immediately.

- Checking Drainage: Ensuring that the condensate drain is clear can prevent water build-up and potential corrosion or mold growth.

3. Signs of Evaporator Issues

Drivers should be aware of signs that may indicate issues with the evaporator, such as:

- Reduced cooling performance

- Unpleasant odors from the ventilation system

- Excessive moisture inside the vehicle

- Visible corrosion or damage to the evaporator unit

سوتشو روجر قطع غيار السيارات المحدودة, المحدوده.

سوتشو روجر قطع غيار السيارات المحدودة, المحدوده.

شركتنا لديها سنوات عديدة من الخبرة في الصناعة, مع الابتكار وجودة الخدمة الممتازة كقدرتنا التنافسية الأساسية, ملتزمون بتزويد العملاء بمنتجات وخدمات عالية الجودة. كشركة رائدة في الصناعة, نلتزم دائما بتوجيه طلب العملاء, ومن خلال البحث والتطوير التكنولوجي المستمر وتحسين العمليات, منتجاتنا لها مزايا تنافسية متميزة في السوق.

شركتنا لديها سنوات عديدة من الخبرة في الصناعة, مع الابتكار وجودة الخدمة الممتازة كقدرتنا التنافسية الأساسية, ملتزمون بتزويد العملاء بمنتجات وخدمات عالية الجودة. كشركة رائدة في الصناعة, نلتزم دائما بتوجيه طلب العملاء, ومن خلال البحث والتطوير التكنولوجي المستمر وتحسين العمليات, منتجاتنا لها مزايا تنافسية متميزة في السوق.