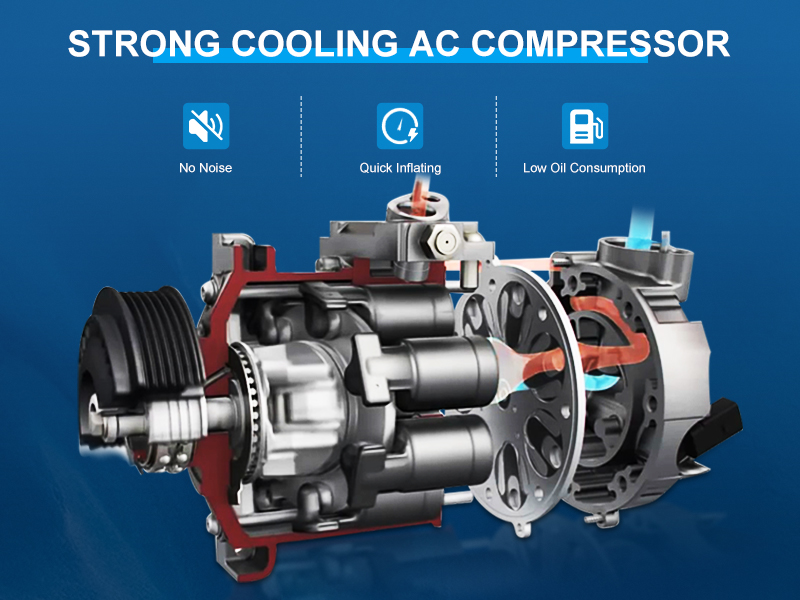

The car air conditioning compressor is the heart of the car air conditioning refrigeration system, playing a role in compressing and delivering refrigerant vapor. There are two types of compressors: fixed displacement and variable displacement. According to different working principles, air conditioning compressors can be divided into fixed displacement compressors and variable displacement compressors. According to different working modes, most compressors can be divided into reciprocating and rotary compressors. Reciprocating compressors have crankshaft connecting rod and axial piston types, while rotary compressors have rotary blade and vortex types.

According to different working principles, air conditioning compressors can be divided into fixed displacement compressors and variable displacement compressors.

Constant displacement compressor

The displacement of a fixed displacement compressor increases proportionally with the increase of engine speed, and it cannot automatically change the power output according to refrigeration needs, and has a significant impact on engine fuel consumption. Its control is generally achieved by collecting temperature signals from the evaporator outlet. When the temperature reaches the set temperature, the compressor electromagnetic clutch is released and the compressor stops working. When the temperature rises, the electromagnetic clutch engages and the compressor starts working. The fixed displacement compressor is also controlled by the pressure of the air conditioning system. When the pressure in the pipeline is too high, the compressor stops working.

Variable displacement air conditioning compressor

The air conditioning control system does not collect temperature signals from the evaporator outlet, but automatically adjusts the outlet temperature by controlling the compression ratio of the compressor based on the pressure changes in the air conditioning pipeline. Throughout the entire refrigeration process, the compressor is always in operation, and the adjustment of refrigeration intensity is completely dependent on the pressure regulating valve installed inside the compressor for control. When the pressure at the high-pressure end of the air conditioning pipeline is too high, the pressure regulating valve shortens the piston stroke in the compressor to reduce the compression ratio, which will reduce the refrigeration intensity. When the pressure at the high pressure end drops to a certain level and the pressure at the low pressure end rises to a certain level, the pressure regulating valve increases the piston stroke to improve the refrigeration intensity.

According to different working modes, compressors can generally be divided into reciprocating and rotary types. Common reciprocating compressors include crankshaft connecting rod type and axial piston type, while common rotary compressors include rotating blade type and vortex type.

1. Crankshaft connecting rod compressor

The working process of this compressor can be divided into four parts, namely compression, exhaust, expansion, and suction. When the crankshaft rotates, the connecting rod drives the piston to move back and forth, and the working volume composed of the cylinder inner wall, cylinder head, and piston top surface undergoes periodic changes, thereby playing a role in compressing and transporting refrigerant in the refrigeration system. The crankshaft connecting rod compressor is the first generation compressor, which has a wide range of applications, mature manufacturing technology, simple structure, and low requirements for processing materials and processes, resulting in a relatively low cost. Strong adaptability, able to adapt to a wide range of pressure and refrigeration requirements, and strong maintainability.

2. Axial piston compressor

Axial piston compressors can be referred to as second-generation compressors, with commonly used types being shaker or inclined plate compressors, which are the mainstream products in automotive air conditioning compressors. The main components of the inclined plate compressor are the main shaft and inclined plate. Each cylinder is arranged circumferentially around the compressor spindle, and the direction of piston movement is parallel to the compressor spindle. The pistons of most inclined plate compressors are made into double headed pistons, for example, in an axial 6-cylinder compressor, cylinder 3 is located at the front of the compressor, and the other 3 are located at the back of the compressor. The double headed piston slides forward and backward in opposite cylinders, with one end of the piston compressing refrigerant vapor in the front cylinder and the other end of the piston inhaling refrigerant vapor in the rear cylinder. Each cylinder is equipped with high and low pressure air valves, and there is also a high-pressure pipe used to connect the front and rear high-pressure chambers. The inclined plate is fixed together with the compressor spindle, and the edge of the inclined plate is fitted into the groove in the middle of the piston. The piston groove and the edge of the inclined plate are supported by steel ball bearings. When the main shaft rotates, the inclined plate also rotates, and the edge of the inclined plate pushes the piston to perform axial reciprocating motion. If the inclined plate rotates once, the front and rear pistons each complete a cycle of compression, exhaust, expansion, and suction, which is equivalent to two cylinders working. If it is an axial 6-cylinder compressor, there are 3 cylinders and 3 double headed pistons evenly distributed on the cylinder section. When the main shaft rotates once, it is equivalent to the action of 6 cylinders.

3. Rotary vane compressor

There are two types of cylinder shapes for rotary vane compressors: circular and elliptical. In a circular cylinder, there is an eccentricity between the main shaft of the rotor and the center of the cylinder, causing the rotor to closely adhere to the suction and exhaust holes on the inner surface of the cylinder. In an elliptical cylinder, the main shaft of the rotor coincides with the center of the ellipse. The blades on the rotor divide the cylinder into several spaces. When the main shaft drives the rotor to rotate one revolution, the volume of these spaces constantly changes, and refrigerant vapor also undergoes changes in volume and temperature within these spaces. The rotary vane compressor does not have an suction valve because the blades can complete the task of suction and compression of refrigerant. If there are two blades, there will be two exhaust processes when the spindle rotates once. The more blades there are, the smaller the exhaust fluctuation of the compressor.

4. Scroll compressor

This type of compressor can be called the 4th generation compressor. The structure of vortex compressors is mainly divided into two types: dynamic and static and double revolution. The most common application of dynamic and static turbines is that their working components are mainly composed of dynamic and static turbines. The structures of dynamic and static turbines are very similar, both composed of end plates and involute spiral teeth protruding from the end plates, with an eccentric configuration and a 180 ° difference between the two. The static turbine remains stationary, while the dynamic turbine, under the constraint of a specialized anti rotation mechanism, is driven by a crank shaft to perform eccentric rotation and translation, that is, there is no self rotation, only revolution. Vortex compressors have many advantages. For example, the compressor has a small volume and light weight, and the eccentric shaft that drives the turbine can rotate at high speed. Because there are no suction and exhaust valves, the vortex compressor operates reliably and is easy to achieve variable speed motion and displacement technology. Multiple compression chambers work simultaneously, resulting in a small gas pressure difference between adjacent compression chambers, less gas leakage, and high volumetric efficiency. Vortex compressors, with their advantages of compact structure, high efficiency and energy saving, low vibration and noise, and reliable operation, have been increasingly widely used in the field of small-scale refrigeration, and have therefore become one of the main directions for the development of compressor technology.

Suzhou Roger Auto Parts Co., Ltd.

Suzhou Roger Auto Parts Co., Ltd.

La nostra azienda ha molti anni di esperienza nel settore, con l'innovazione e l'eccellente qualità del servizio come nostra competitività principale, impegnati a fornire ai clienti prodotti e servizi di altissima qualità. In qualità di leader del settore, Aderiamo sempre all'orientamento alla domanda del cliente, e attraverso la continua ricerca e sviluppo tecnologico e il miglioramento dei processi, I nostri prodotti hanno eccezionali vantaggi competitivi sul mercato.

La nostra azienda ha molti anni di esperienza nel settore, con l'innovazione e l'eccellente qualità del servizio come nostra competitività principale, impegnati a fornire ai clienti prodotti e servizi di altissima qualità. In qualità di leader del settore, Aderiamo sempre all'orientamento alla domanda del cliente, e attraverso la continua ricerca e sviluppo tecnologico e il miglioramento dei processi, I nostri prodotti hanno eccezionali vantaggi competitivi sul mercato.